In Mold Decoration - IMD FILM -

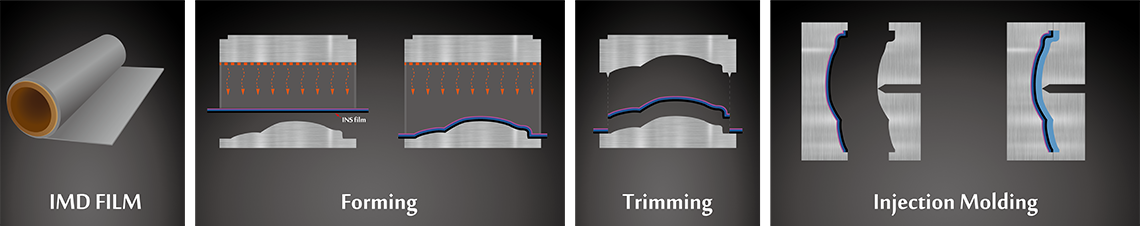

In-Mold Decoration (IMD) is one of the most popular injection molding techniques chosen by the automotive and electronic industry. Insert injection molding combines the thermoforming of decorative film laminates with injection molding. In this process, laminates first are thermoformed into complex shapes and trimmed to match a complex injection mold cavity.

In Mold Decoration (IMD) Process

IMD Film Advantages

- It Eliminates secondary operations.

- High precision parts and reduce reject rate from secondary decoration.

- High Durability, e.g chemical and scratch resistant.

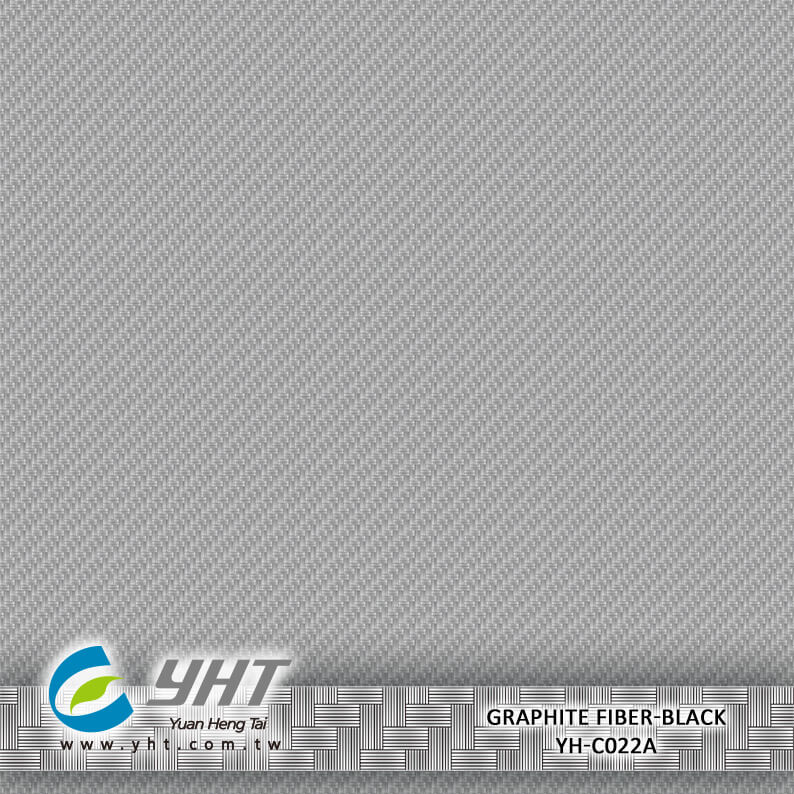

- IMD films can create a huge variety of visual effects, e.g surface texture, metallic or functional printing.

- Decoration can be changed by simply inserting different print films from shot to shot.

- Environmentally friendly, with the reduction of raw material such as metals and reduction of facility space and energy.

- Unique and sophisticated appearances.

Applications

The surface decoration produced by this technical method is often used in the automotive, electrical appliances, and medical devices industries.

Automotive Industry

Electronic Appliances

Medical Devices

YHT- IMD Film features

We are confident that we can provide you with the highest level of Film Insert Molding (IMD/FIM) film services.

Thanks to our technology, printing experience and pattern development, we can provide unique features on your products surfaces which cannot be added by other conventional printing or painting processes. Our film features include:

2. Stretchable-Deeper curved shaped angle. IMD can be used in 3D shaped parts and curved angles. But many factors must be considered i.e., shape, size, depth of draw, type of film required and more.

4. IMD films are also compatible with circuits or electronics integration. (IME)

5. 2H coating hardness. Above market standards.

6. The films are not easy to deform.

8. No secondary decoration. After injection IMD films don’t need further procedures, such as printing or painting.

9. Our IMD films can be applied on any type of material the customer request

When considering the differences with other printing methods, IMD gives any OEM customer an opportunity to bring a greater level of sophistication & aesthetic to any product. By working closing with our design department it is possible to let your inner artistry loose and create the exact film design you are looking for.

For automotive interiors there is an increasing demand of higher levels of decoration, in order to satisfy the demand of their customers, OEMs are force to find new technologies without increasing costs. As we all know, paint is one of the most expensive components on a car, paint line is the biggest investment in an automotive assembly plant occupying half the plant floor space. In Mold Decoration is one of the top decoration technologies for the automotive industry, it eliminates the need for separate steps, such as coating or painting, even in-cases of complex 3D shaped objects. It also lowers scrap rates and improves recyclability. Also offering manufacturers, extensive flexibility in design and manufacturing with a considerable savings in costs, time, and machine investment.

_spic.jpg)