How In-Mold Decoration Films are Revolutionizing the Automotive Industry- Interior Design

In recent years, the automotive industry has transformed its interior design with groundbreaking advancements in In-Mold Decoration (IMD) film technology. Cars are no longer seen as just transportation but as personal havens prioritizing comfort and luxury over mere functionality. IMD has not only reshaped automotive aesthetics but also revolutionized how designers implement their ideas. As we explore into how IMD films are altering the industry, we'll explore opportunities for innovation. We ask ourselves “What more can we bring to this competitive IMD market?” Our answer lies in our IMD films, showcasing endless possibilities.

Applications of IMD Film in the Automotive Industry

With the rise of futuristic car designs and the evolving ergonomics of car interiors, the scope for using In-Mold Decoration films is expanding.

Besides the above parts, In Mold Decoration films can also be used for steering wheels, trim panels, shift knobs, seat backs, storage compartments and more.

Benefits of IMD film

Read more about the benefits of In Mold Decoration films here.

Among the main advantages of In Mold Decoration, we find the following:

-

With IMD, the decorative film is placed into the mold cavity before injection, allowing the decoration to become an integral part of the molded part. This eliminates the need for additional steps like painting, printing, or applying decals after molding, streamlining the production process and reducing costs.

-

IMD offers high Durability, e.g chemical and scratch resistant.IMD offers high Durability, e.g chemical and scratch resistant.

-

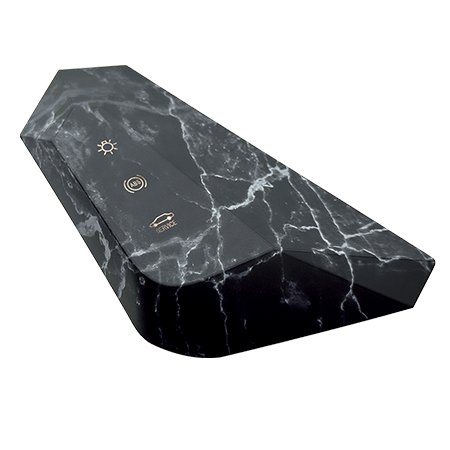

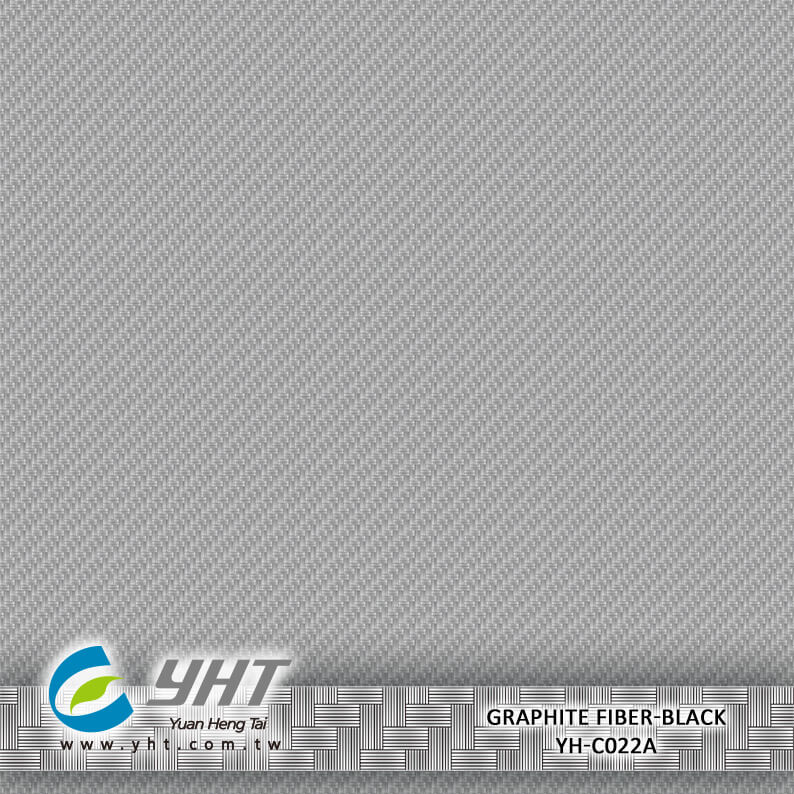

IMD films can create a huge variety of visual effects, e.g surface texture, metallic or functional printing.IMD films can create a huge variety of visual effects, e.g surface texture, metallic or functional printing.

-

Decoration can be changed by simply inserting different print films from shot to shot.

-

Environmentally friendly, with the reduction of raw material such as metals and reduction of facility space and energy.

What makes YHT IMD films special for the automotive industry?

Our technology focus mainly in 4 aspects:

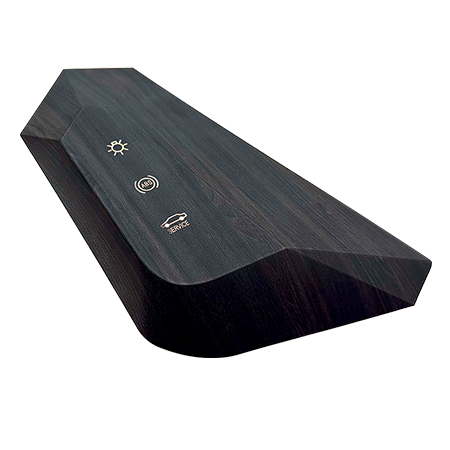

1. DEEP TEXTURE - Post-injection molding

Our deep texture IMD film goes beyond appearance; you experience it. Incorporating realistic texture transforms a simple plastic surface into a tangible experience, enhancing both the look and feel.

2. 2H HARDNESS

It's not just about looks; it's about making sure your car stays stylish and good despite everyday wear and tear.

3. STRETCHABLE- Deep Curved Shaped Angle

During injection molding, film's stretchability ensures that every curve and detail is covered seamlessly, delivering that polished, premium look throughout the entire interior.

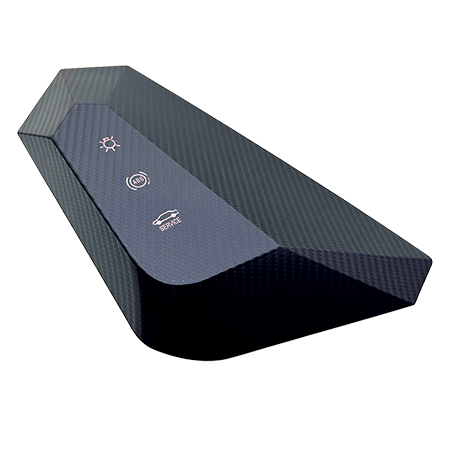

4. OPTIMIZED FOR ELECTRIC TOUCH FUNCTION or IME

Imagine a special film that not only makes things look good but also works with touch functions, circuits and In-Mold Electronics. It's like having a cool design that's also smart and functional, making your car look awesome and work better. Besides the above, our IMD films can incorporate high-end appearances, capacitive touch, back-lighting, and dead-front graphics.

Film Materials and Process

In-Mold Decoration requires films with dimensional stability to withstand the heat and pressure in the molding process. Thinner films prevent gate wash, while thicker ones are ideal for deeper draws. UV, chemical, and abrasion-resistant films enhance durability and contribute to IMD overall success.

YHT IMD films are versatile, suitable for various materials. The choice depends on specific application requirements. Common materials include PC, PET, Glassfiber, ABS, PC/ABS, PMMA. Selection is based on desired characteristics like durability, transparency, heat resistance, and aesthetic appeal.

Read here to understand the IMD process.

Automotive OEM’s

After a decade of research and perfecting our IMD film technology, we proudly introduce our films to the market for the first time at the Automotive Interior Expo 2023 in Stuttgart, Germany.

The exhibition showed a strong market demand for films with characteristics like ours. We emphasized the immense potential of the IMD decoration market in the automotive industry, showcasing how our innovative IMD film technology can make a substantial contribution.

Future Outlook of IMD films

Technology Improvements

Our observation from the exhibition last December highlighted the growing demand for authentic textures on decorative surfaces. Simply looking good and luxurious is no longer sufficient; the market now calls for the ability to touch, feel, and interact with the surface of your car.

Design Trends Predictions

In terms of market trends, there is a growing demand for larger displays, capacitive touch, and hidden-til-lit features in the automotive industry. The trend of having a display that spans the entire width of the cockpit is expected to continue. Piano black, a high-gloss effect, has been popular for at least 20 years and remains a sought-after finish. There is also a trend towards using IMD for creating seamless backsplashes, as it allows for a flat appearance with no edge, and in-mold appliques bring variability to the options for decorating.

Conclusion

In the automotive industry, design trends that incorporate full-color, multifunction touchscreens and capacitive switches are displacing traditional mechanical and resistive touch UI with IMD-FIM (film insert molding) on auto and appliance applications. IMD film technology has revolutionized automotive interior design, shifting from traditional views of cars to new levels of luxury and comfort. Beyond aesthetics, In Mold Decoration transforms the very essence of the automotive concept. IMD-FIM is a perfect fit, with rapid change.

If you need IMD films, you are using IMD technology, or you are interested in this product, you are welcome to contact us at [email protected]

_spic.jpg)