IMD Process

2024-01-11

YHT IN-MOLD DECORATION

EXPLAINING THE PROCESS

IMD Film

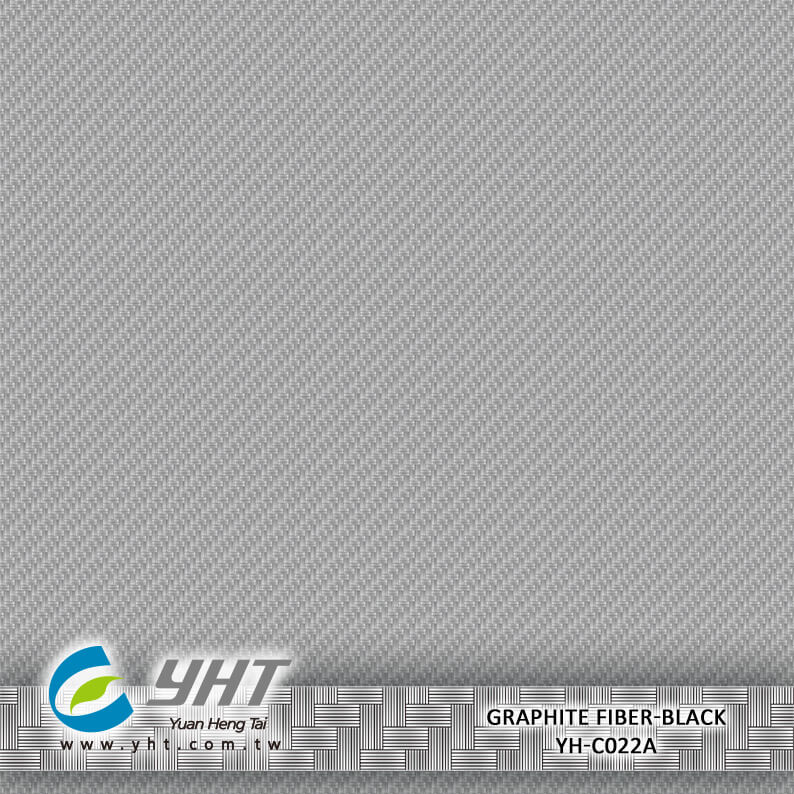

- Deep real-like texture feeling

- 2H Hardness

- Stretchability

- Compatibility with IME/Electric touch function

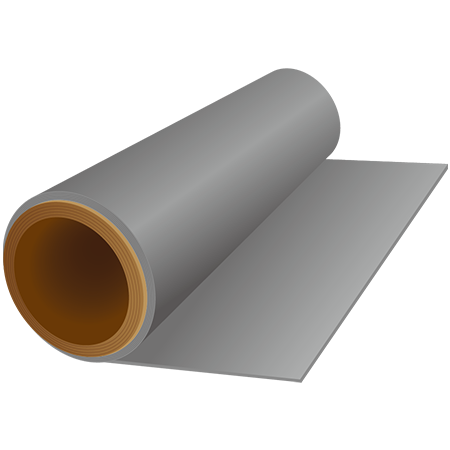

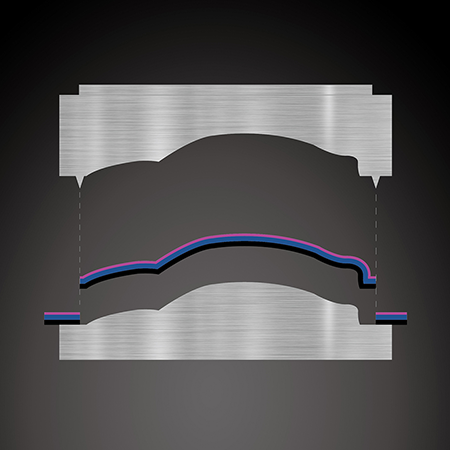

STEP 1: Forming

In the "Forming" step of In Mold Decoration (IMD), a decorated film is placed into a mold. When heat is applied, the film softens and takes the shape of the mold. As it cools, the film adheres permanently to the molded part, creating a seamless and durable decoration. This process ensures a precise and integrated design on the final product.

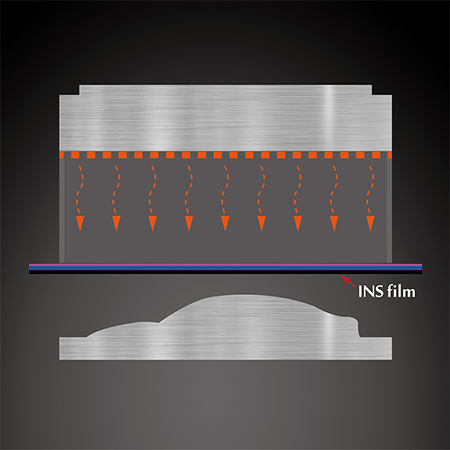

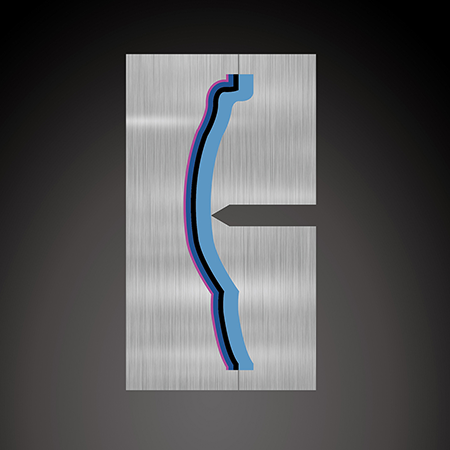

STEP 2: Trimming

In the "Trimming" phase of In Mold Decoration (IMD), excess material from the decorated film is carefully removed to achieve the final, precise shape. This step ensures that the decoration aligns perfectly with the contours of the molded part, leaving a polished and seamless finish. Trimming is crucial for maintaining the integrity of the design and achieving a high-quality, visually appealing end product.

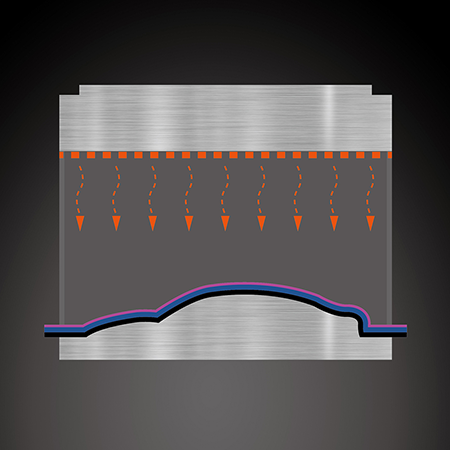

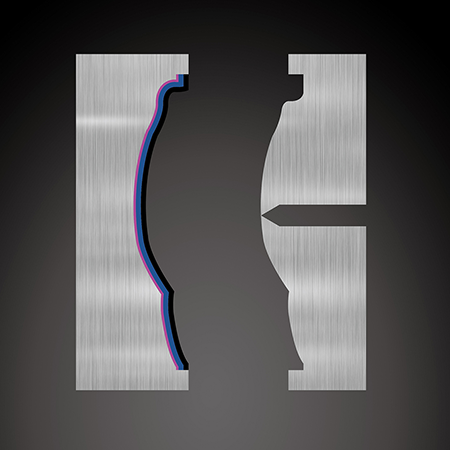

STEP 3: Injection Molding

In the "Injection Molding" stage of IMD, the decorated film is placed into a mold cavity. Molten plastic is injected into the mold, surrounding the film. As the plastic cools and solidifies, it merges with the film, creating a fully integrated and decorated part. This process not only imparts a visually appealing design but also ensures a durable and functional final product through the seamless union of decoration and structure.

Understand more about our IMD Films here

For any inquiries don’t hesitate to reach out to us at [email protected]

_spic.jpg)