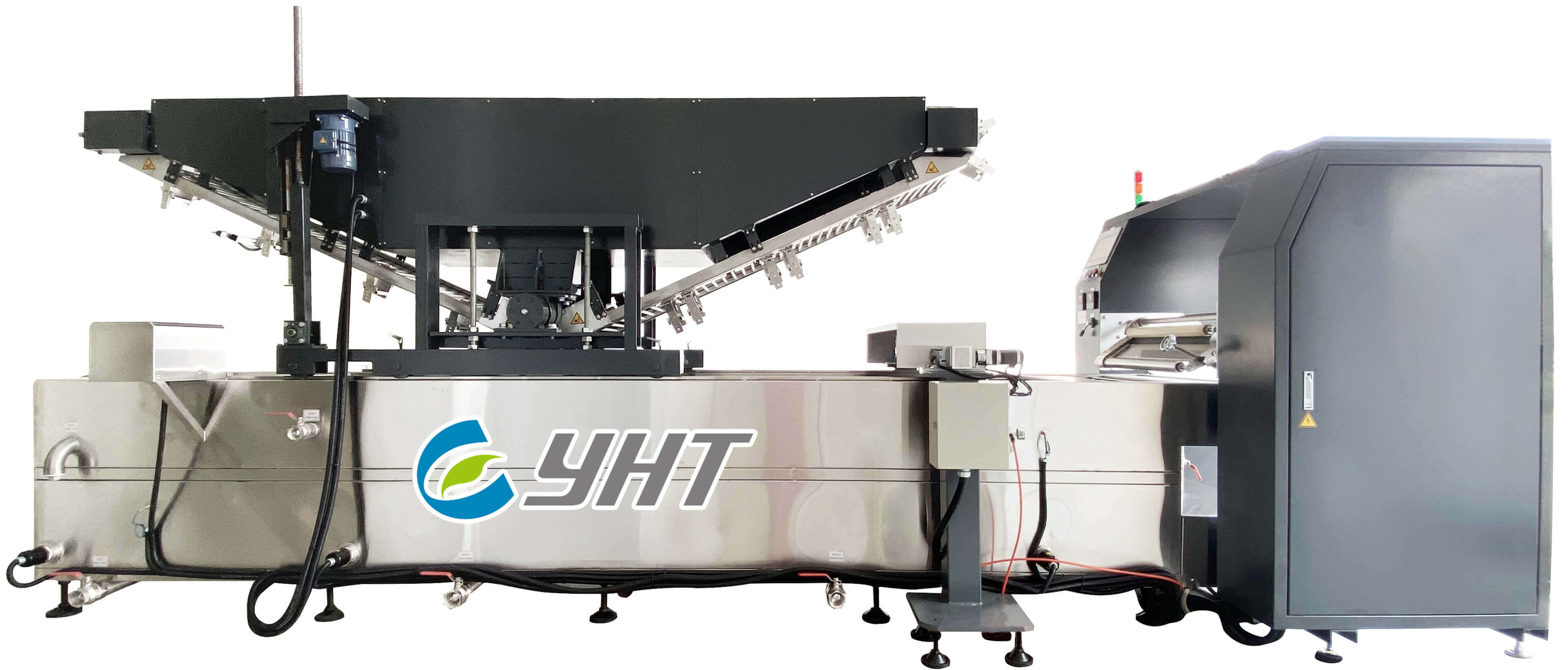

JK-350TT

Automatic Continuous Flow Dipping Machine with Tri-con

The Automatic Continuous Flow Dipping Machine with Triangle System is an advanced, automated water transfer printing solution engineered for high-volume and continuous production lines. This machine combines intelligent film feeding, automatic activator spraying, and precise dipping control, making it ideal for manufacturers who require consistent, efficient, and large-scale operation.

Key Features:

- Triangle Dipping System

This system allows for simultaneous operations: one arm loading and one unloading. This cycle boosts output and ensures smooth workflow without interruption.

- Automated Workflow

From film feeding, film positioning, activator spraying to immersion, everything is fully automated, reducing labor requirements and operator error.

- Continuous Film Flow System

Advanced film control technology ensures consistent tension and precise alignment throughout the process, essential for long runs and high-speed operation.

- Auto Spray System

Integrated automatic spray arms apply activator uniformly across the film surface, guaranteeing consistent print transfer while minimizing waste and overspray.

- High-Quality Stainless Steel Tank

Constructed from durable 304 stainless steel, the tank resists corrosion and ensures long-term use in demanding industrial environments.

- PLC Touchscreen Interface

User-friendly interface allows precise control over all parameters, immersion time, speed, spray timing, providing easy adjustments and reliable repeatability.

Applications:

Perfect for industries with mass production needs such as:

Automotive components

Motorcycle parts

Household items

Sporting goods

Advantages:

Continuous flow design significantly increases throughput

Reduces operator fatigue and training time

Ensures consistent, high-quality decoration on every part

Key Features:

- Triangle Dipping System

This system allows for simultaneous operations: one arm loading and one unloading. This cycle boosts output and ensures smooth workflow without interruption.

- Automated Workflow

From film feeding, film positioning, activator spraying to immersion, everything is fully automated, reducing labor requirements and operator error.

- Continuous Film Flow System

Advanced film control technology ensures consistent tension and precise alignment throughout the process, essential for long runs and high-speed operation.

- Auto Spray System

Integrated automatic spray arms apply activator uniformly across the film surface, guaranteeing consistent print transfer while minimizing waste and overspray.

- High-Quality Stainless Steel Tank

Constructed from durable 304 stainless steel, the tank resists corrosion and ensures long-term use in demanding industrial environments.

- PLC Touchscreen Interface

User-friendly interface allows precise control over all parameters, immersion time, speed, spray timing, providing easy adjustments and reliable repeatability.

Applications:

Perfect for industries with mass production needs such as:

Automotive components

Motorcycle parts

Household items

Sporting goods

Advantages:

Continuous flow design significantly increases throughput

Reduces operator fatigue and training time

Ensures consistent, high-quality decoration on every part

Model: JK-350TT

| Category | Item | Specification |

| General | Dimension | 578 x 182.5 x 245 cm (L x W x H) |

| Total Machine Weight | 1820kgs | |

| Capacity |

Continuous Film Flow 1.2M ~ 1.5M / per minute (According to product) |

|

| WTP Max size | Width-600mm;Length-700mm | |

| Power Consumption | 30 kw* | |

| Activator Auto-Spray | Equipped | |

| Main Machine | Dimension | 180 x 100 x 205.5 cm (L x W x H) |

| Control Panel | Touch Panel | |

| Triangle | Dimension | 3910 x 1105 x 1580 mm (L x W x H) |

| Transmission | Stable Fixed Chain | |

| Fixture Stand | Recommend 15 - 22 sets | |

| Dipping Tank | Dimension | 500 x 130 x 117.5 cm (L x W x H) |

| Material | Stainless Steel 304 | |

| Heater | Installed | |

| Guiding Chain | Installed | |

| Water Circulation | Dual-Filter System | |

| Water Usage | 4000 Liters | |

| Auto Spray System | Dimension | 182.5 x 40 x 118 cm (L x W x H) |

| Material | Iron Coating and Aluminum |

*The power consumption stated is for reference only and may vary depending on the required voltage.