Water Transfer Printing Solutions for Industrial Applications

Looking for a reliable partner in Water Transfer Printing? YHT offers comprehensive hydrographic printing solutions tailored for automotive, aerospace, consumer electronics, and lifestyle product manufacturers. With over 30 years of experience, we provide high-quality hydro dipping films, precision-engineered water transfer printing machines, and full-process training and support to streamline your surface decoration production. Whether for mass production or customized finishing, our water transfer systems ensure vibrant, durable results on any complex 3D object.

What Is Water Transfer Printing

Water Transfer Printing — also known as Hydro Dipping, Hydrographic Printing, or Hydro Transfer Printing — is a surface decoration technique that uses water to apply printed patterns to three-dimensional objects. The process involves placing a water-soluble film with a printed design onto the water’s surface, spraying it with activator to liquefy the pattern, and then immersing the object so the design adheres uniformly, even on complex curves and textures.This innovative method is widely used to apply finishes like carbon fiber, wood grain, camouflage, and metallic textures to automotive parts, helmets, appliances, electronics, and more. It is both cost-effective and versatile, making water transfer printing ideal for industries seeking high-quality, scalable, and aesthetically pleasing results.

Want to dive deeper? Read our Beginner’s Guide to Water Transfer Printing to learn the full process and get started today.

News

From news you can find anything we would like to update to you. Such as new patterns, any events

Browse 3000+ Hydrographic Films – Find Your Pattern Now

Explore our extensive collection of hydro dipping films — from realistic wood grain and brushed metal to dynamic camouflage and carbon fiber textures. Each design is compatible with industry-standard water transfer printing systems and offers superior adhesion, color depth, and durability. Choose from over 3,000+ patterns and bring any product surface to life.

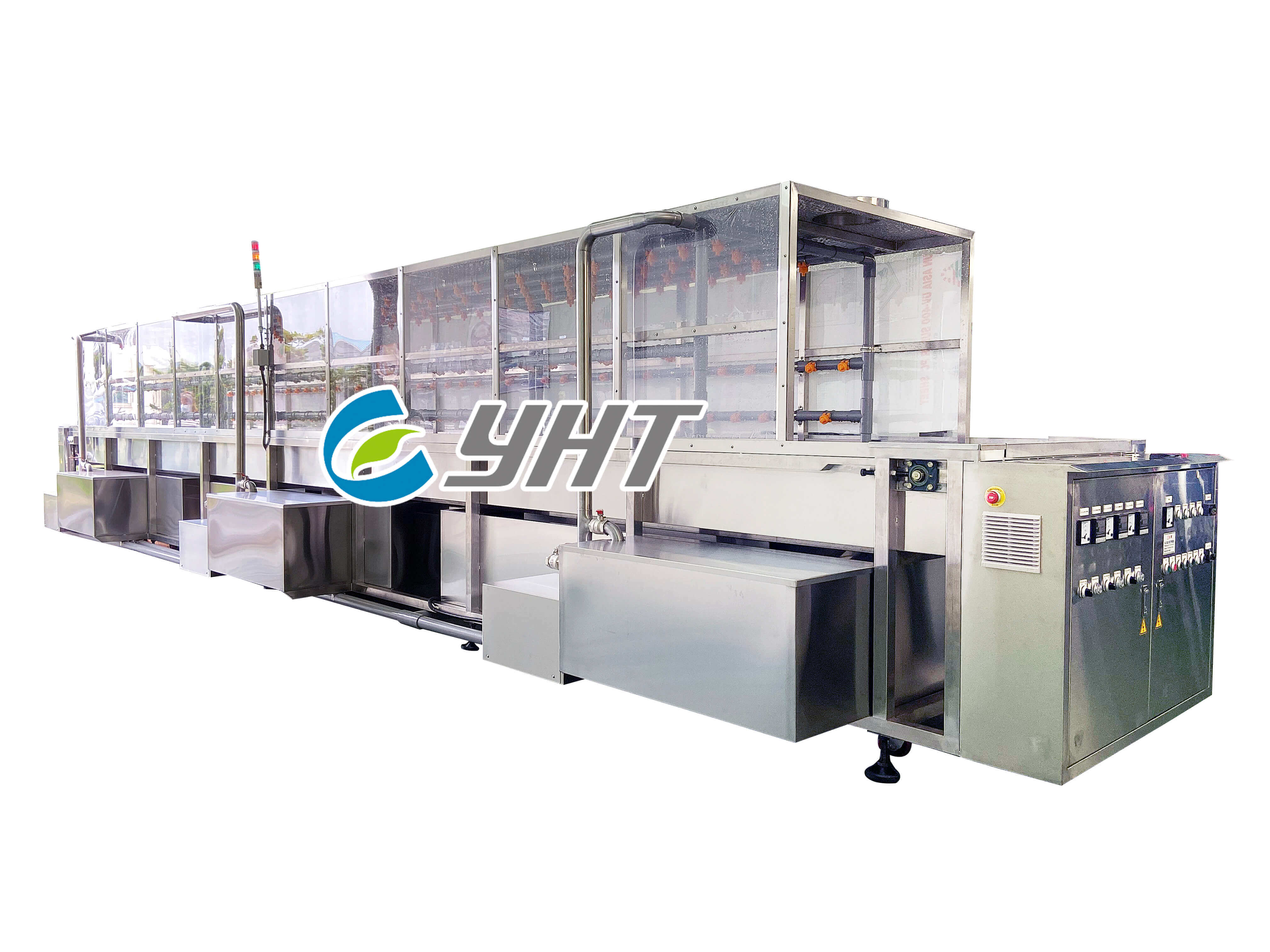

Water Transfer Printing Machines & Hydro Dipping Equipment

Backed by 30+ years of innovation in water transfer technology, YHT designs and manufactures a full range of hydrographic printing machines tailored to meet different production needs. From semi-automatic dipping stations to fully automated conveyor systems, our equipment ensures high efficiency, low failure rates, and user-friendly operations. Key machine types include:Semi-Auto Hydro Dipping Machine with Production Arm,Automatic Continuous Flow Transfer System,Integrated Spray + Dipping Workstations,Water Washing & Drying Stations,etc.

Industries We Serve with Water Transfer Technology

Hydrographic water transfer printing is widely used in both consumer and industrial applications. Whether you're decorating auto interiors, hunting gear, or sports accessories, our solutions adapt to every surface and sector. Popular applications include: Automotive Interior Trim Panels, Firearms & Outdoor Equipment, Electronic Device Casings, Aircraft & Marine Interiors and Daily Lifestyle Products, etc.

Video

See the water transfer printing process in action. Our videos showcase both semi-automatic and continuous flow dipping machines, highlighting the transformative power of hydrographic technology on complex 3D objects.

_pic.jpg)